Subtotal: $0.00

Bearings

Course Overview

This course consists of three lessons designed for the training of bearings. Topics covered include the importance of bearings in machinery operation, concept of load and how it affects bearings, and housings. Additionally, the main types of bearings are discussed: plain, anti-friction, and thrust bearings.

Course Objectives

- Describe bearings and their importance in machinery operation.

- Introduce the concept of load and how it effects bearings.

- Explain the purpose of housings.

- Explain the use of PLAIN bearings.

- Explain the use of ANTI-FRICTION bearings.

- Explain the use of THRUST bearings.

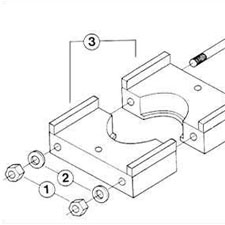

- Dismount anti-friction bearings using a bearing press and/or a bearing puller

- Inspect the bearing for signs of failure

- Clean the shaft and check for taper and out-of-round using the proper measuring instruments

- Clean the housing and check for damage

- Select the proper bearing for replacement, if necessary

- Properly orient a bearing prior to installation

- Mount a bearing using an induction heater and/or an arbor press

- Measure the bearing’s inner and outer clearances during installation

- Properly lubricate bearings per manufacturers’ recommendations

Included Modules

- Introduction to Bearings: was designed for employees in all disciplines as well as for the multi-craft training needs of process and manufacturing facilities. The lesson describes the purpose and the basic components of bearings. The lesson also introduces the identification and proper usage of bearing types.

- Analyzing Bearing Failure: Explains the purpose of bearings and demonstrates how bearings reduce friction and maintain the alignment of operating equipment. The basic operation of anti-friction bearings and plain journal bearings is demonstrated as well as the importance of full fluid film lubrication and proper lubrication clearance. Additionally, indications of various premature bearing failures are discussed.

- Maintaining Bearings: Reducing Failure Rate: Explains and demonstrates how to clean and disassemble bearing housings and how to dismount, inspect, and mount common types of bearings. The importance of cleanliness and following manufacturers’ instructions are stressed throughout each demonstrated procedure.