Filters and Lubrication Maintenance

Filters and Lubrication Maintenance

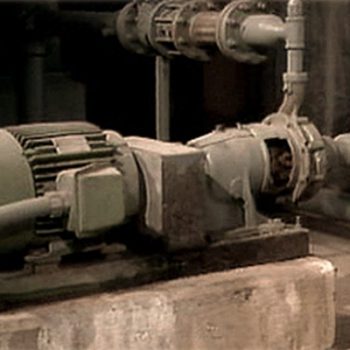

This is the final lesson in the Industrial Lubrication Course. Participants also learn the importance of following lubrication schedules, how to change common types of oil filters. This lesson explains the purpose of filters and the importance of filter maintenance in lubrication systems. Additionally, the lesson indicates the benefits of oil sampling and analysis and identifies several factors, which can cause lubrication failure.

Course Overview

This course is designed for training oilers, mechanics, and millwrights as well as for the multicraft needs of process and manufacturing facilities. Participants are trained to recognize various types of lubrication systems and their maintenance requirements, including ring, bath, splash, constant level, and forced feed lubrication systems, as well as understand how they operate. Participants also learn the importance of following lubrication schedules, how to change common types of oil filters, and how to properly handle and store lubricants to prevent lubricant contamination.

Module Overview

This is the final lesson in the Industrial Lubrication Course. Participants also learn the importance of following lubrication schedules, how to change common types of oil filters. This lesson explains the purpose of filters and the importance of filter maintenance in lubrication systems. Additionally, the lesson indicates the benefits of oil sampling and analysis and identifies several factors, which can cause lubrication failure.

Module Objectives

- Explain the purpose of filters in a lubrication system.

- Explain the differences between surface filters and depth-type filters.

- Explain why filter maintenance is important.

- Recognize indications that a filter must be cleaned or replaced.

- Explain the benefits of following a lubrication schedule.

- Interpret information on a lubrication schedule.

- Explain the benefits of oil sampling and analysis.

*A one-year SkillGRID subscription is required for all new users, billed at $12/year.