Subtotal: $0.00

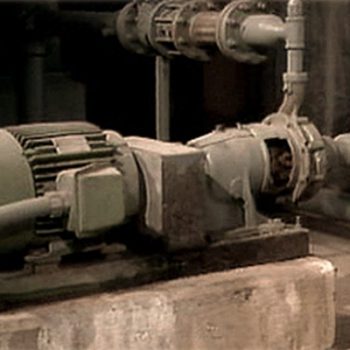

Centrifugal Pump Repair

Overview

This course is designed for all levels of maintenance personnel as well as for the multicraft training needs of process and manufacturing facilities. Participants should be familiar with the basic operation of centrifugal pumps. This course consists of six modules covering excessive leakage, temperature, loss of capacity, disassembly, inspection, and reassembly.

Objectives

- Identify and describe the sealing surfaces on a centrifugal pump.

- Explain the purpose and conditions under which packing would be used.

- Explain the purpose of the lantern ring.

- Explain the purpose and conditions under which a mechanical seal would be used.

- Explain how to determine whether centrifugal pump leakage is excessive.

- Recognize causes and symptoms of excessive leakage.

- Explain the purpose of bearings in a centrifugal pump.

- Explain how normal operating temperature is maintained in a centrifugal pump.

- Recognize causes of symptoms of excessive temperature in a centrifugal pump.

- Discuss causes of symptoms of excessive temperature in a centrifugal pump.

- Explain how pressure and flow rate are affected by the system in which a pump operates.

- Recognize and discuss causes of symptoms of loss of capacity/loss of head.

- Explain what occurs during cavitation.

- Explain the causes and symptoms of worn components.

- Identify main components of a typical end suction pump.

- Explain the function of the components of a typical end suction pump.

- List and demonstrate the preparation for pump disassembly.

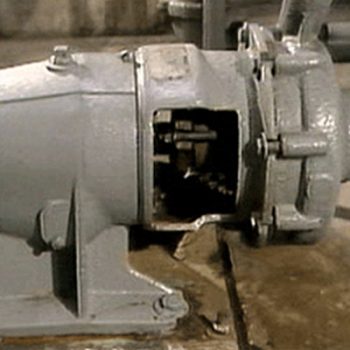

- Disassemble a typical end suction pump.

- Inspect the components of a centrifugal pump.

- Measure the bearing seat on the shaft of a centrifugal pump.

- Measure shaft runout.

- Recognize evidence of cavitation on an impeller.

- Explain the importance noting measurements in a maintenance log.

- Reassemble a typical end suction pump.

- Check impeller clearance.

- Calculate the thickness of shims needed to correct impeller clearance.

- Determine the gasket size needed in the bearing end cap.

- Install a mechanical seal.

Modules

Showing all 6 results