Surface Facilities Primer

Surface Facilities Primer

Course Overview

The Surface Facilities Primer introduces the equipment typically used to process fluids produced from oil wells, describing the identification, internal configuration, principles of operation, and contribution to the overall system of each of the major pieces of oilfield surface equipment. Emulsion breaking and the separation of oil, gas, and water are discussed. The course also covers the handling, storage, and transportation of hydrocarbons produced from the well. Two subjects in particular are afforded specific attention in this course: One module covers the function and operation of reciprocating compressors. Another provides detailed procedures for coupling alignment. The Surface Facilities Primer course comprises four computer-based training modules, each one representing over an hour and a half of instruction and exercises.

Course Objectives

- Identify each major piece of oilfield surface equipment.

- Trace the route of all produced fluids from the wellhead through their final application.

- Explain the basic function and process of fluid separation.

- Describe the various techniques and equipment used to break emulsions.

- Identify the name, function, interior configuration, and general operating principle of each major piece of oilfield surface equipment.

- Describe how each fluid stream is handled, from the wellhead through its final disposition.

- Explain how oil and gas are measured before leaving the facilities.

- Function and Operation of Reciprocating Compressors.

- Coupling Alignment.

Included Modules

- Coupling Alignment: This module explains the importance and function of coupling alignments. Tools and equipment used in alignment procedures are described, together with various alignment conditions. Preliminary checks and alignment techniques are presented step by step.

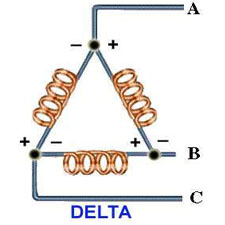

- Reciprocating Compressors: This module explains the operating principles and field applications of reciprocating gas compressors. It compares natural gas drivers with electrical drivers, and describes the function of aerial coolers. The module concludes with a discussion of gas flow control systems.

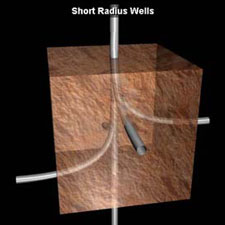

- Surface Facilities Volume 1: The two main functions of surface facilities are explained in this module: separating oil, water, and gas; and testing production capability. The module describes surface system components, processes for separating fluids and breaking emulsions, and well testing facilities.

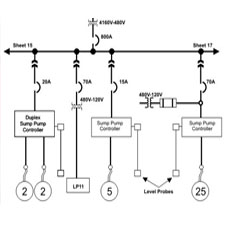

- Surface Facilities Volume 2: The second Surface Facilities module details the handling of crude oil, natural gas, and water produced from a well. Metering systems, storage facilities, and transportation options for oil and gas are described, along with treatment and disposal alternatives for waste water.